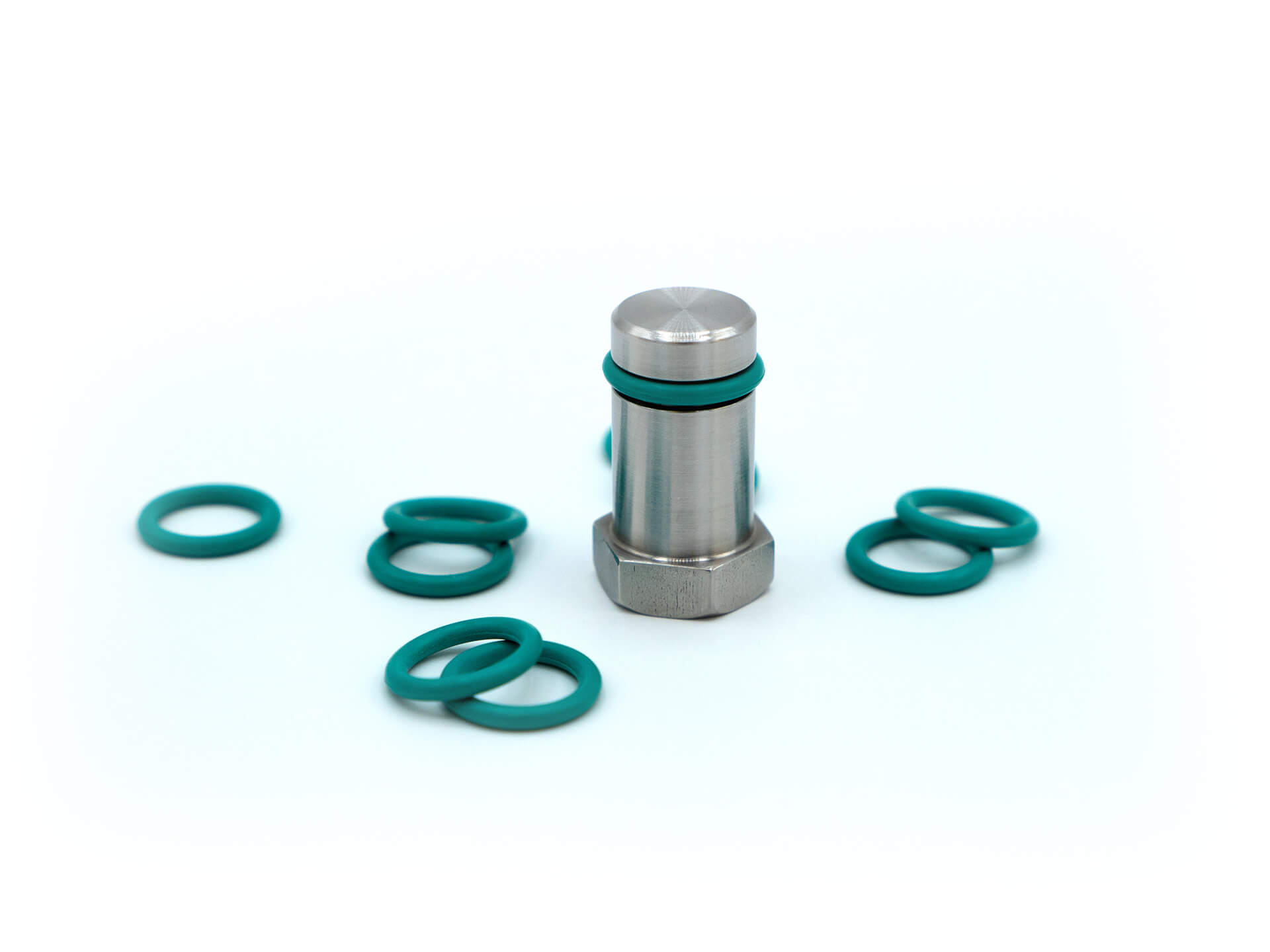

SMR Sondermaschinen GmbH has developed an individual and innovative solution for the installation of external o-rings. Our patented o-ring assembly unit can easily be integrated into your system by taking over the controls. Our o-ring assembly unit is customized to your individual requirements (o-ring dimensions). After all, SMR Sondermaschinen GmbH stands for individual solutions that are tailored to the needs of our customers —there is no better way for you to make o-ring installation purposeful and profitable.

Increased efficiency thanks to individual concepts

Whether pertaining to spiral conveyors, rotary transfer machines or o-ring assembly units-replacing standardized compromise solutions with individual strategies and concepts is the fastest way for entrepreneurs to gain efficiency in production. Thanks to the versatile options with which we are able to tailor o-ring assembly even more precisely to your needs, we optimize your output. From conceptual consultation to construction and the installation of your new o-ring assembly unit, this is why we stand as experts by your side. Contact us.

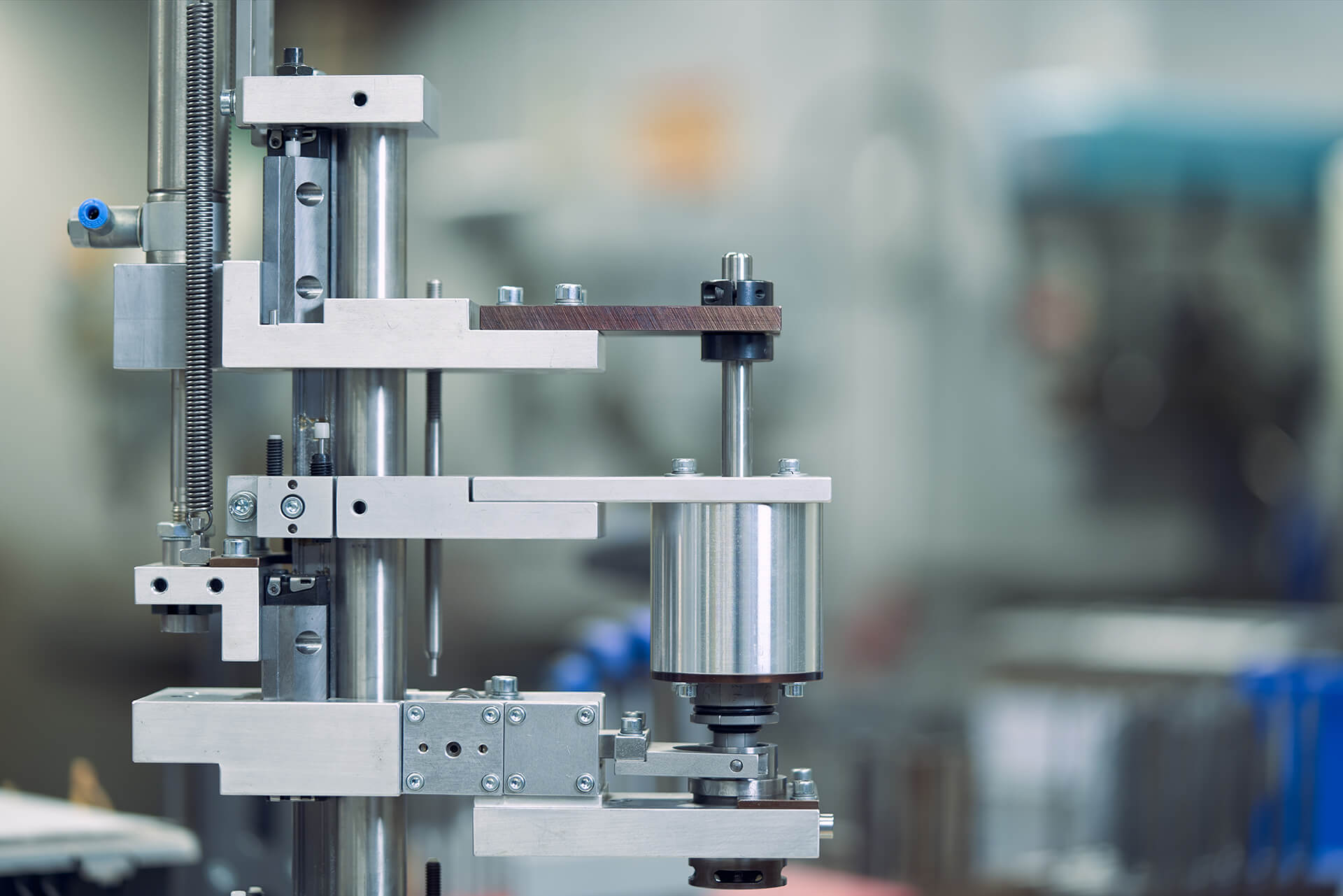

Feeding, positioning, installing - o-ring assembly

On one hand, o-ring assembly is about precision, on the other speed. The sophisticated technology of our o-ring assembly unit reliably achieves both. Especially when combined with one of our spiral conveyors, the efficiency of the unit can be additionally increased.

Simplicity - the guarantee for success

The o-ring assembly in our unit takes place after separation in the spiral conveyor. The o-ring is then mechanically clamped using a collet chuck. After the mounting position has been achieved, the tension is released so that the o-ring jumps into the component’s o-ring groove. The simple function of the mechanism ensures o-ring assembly that is less prone to errors or inaccuracy.

Maximum precision thanks to manual adjustment

To ensure that the unit delivers exact results during o-ring assembly and guarantees fast operation, all distances and end positions can be precisely set. For these purposes, there are various adjustment elements. We would be happy to train your employees on-site to get your company working with your new o-ring assembly unit to quickly achieve new efficiency and profitability. Generally, cycle times are approximately five seconds.

SMR Sondermaschinen GmbH: your solution for o-ring assembly

Since 1991, SMR Sondermaschinen GmbH has stood for the recognizing as well as solving of problems and demands in automation processes. With individually planned special-purpose machines, customized assembly systems and rotary transfer machines as well as our solution for o-ring assembly, we ensure process optimization as well as more precision and quality in the results. This is not only possible thanks to our great expertise and innovative concept solutions, but above all because we focus on you as our customer. We offer you complete solutions from a single source—tailor-made and designed for a perfect fit. Take us at our word and convince yourself during a personal consultation. We would be happy to make you an offer that suits you and your needs.