With the Centrifugal Feeder BG500, SMR Sondermaschinen GmbH has developed its own design which, in comparison to previous solutions, not only works more efficiently, but also more individually. This centrifugal feeder accurately positions customer-specific components with a surface of up to approx. 60 x 60 mm. If these parts are symmetrical, quantities of up to 60,000 per hour can be achieved. Yet another advantage: Because of the modular design of our centrifugal feeder, it is possible to tailor the system to your specific needs. Even a ready-made centrifugal feeder can be converted or expanded at any time—even directly at your facilities. Thanks to customized solutions, you not only save time and money, but also gain flexibility.

Capacity for innovation leads to tailored solutions

At SMR GmbH we are always looking for new solutions in order to meet existing demands even better and more precise. Our Centrifugal Feeder BG500 is an excellent example of this—its strength lies not only in its speed, but above all in its variability. We would be happy to tell you more about what our centrifugal feeders can offer you. Contact us.

Turning, sorting, ejecting - centrifugal feeders

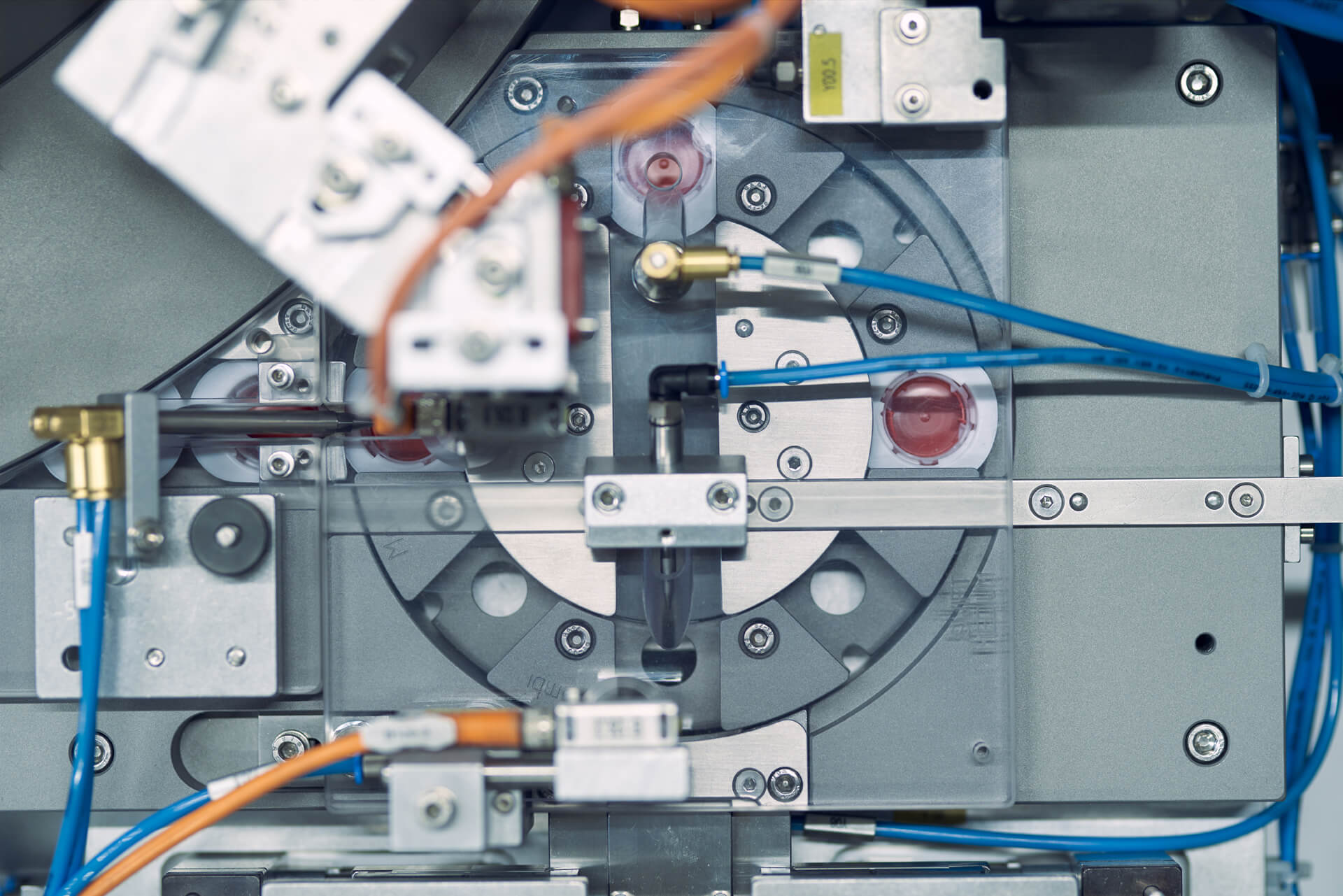

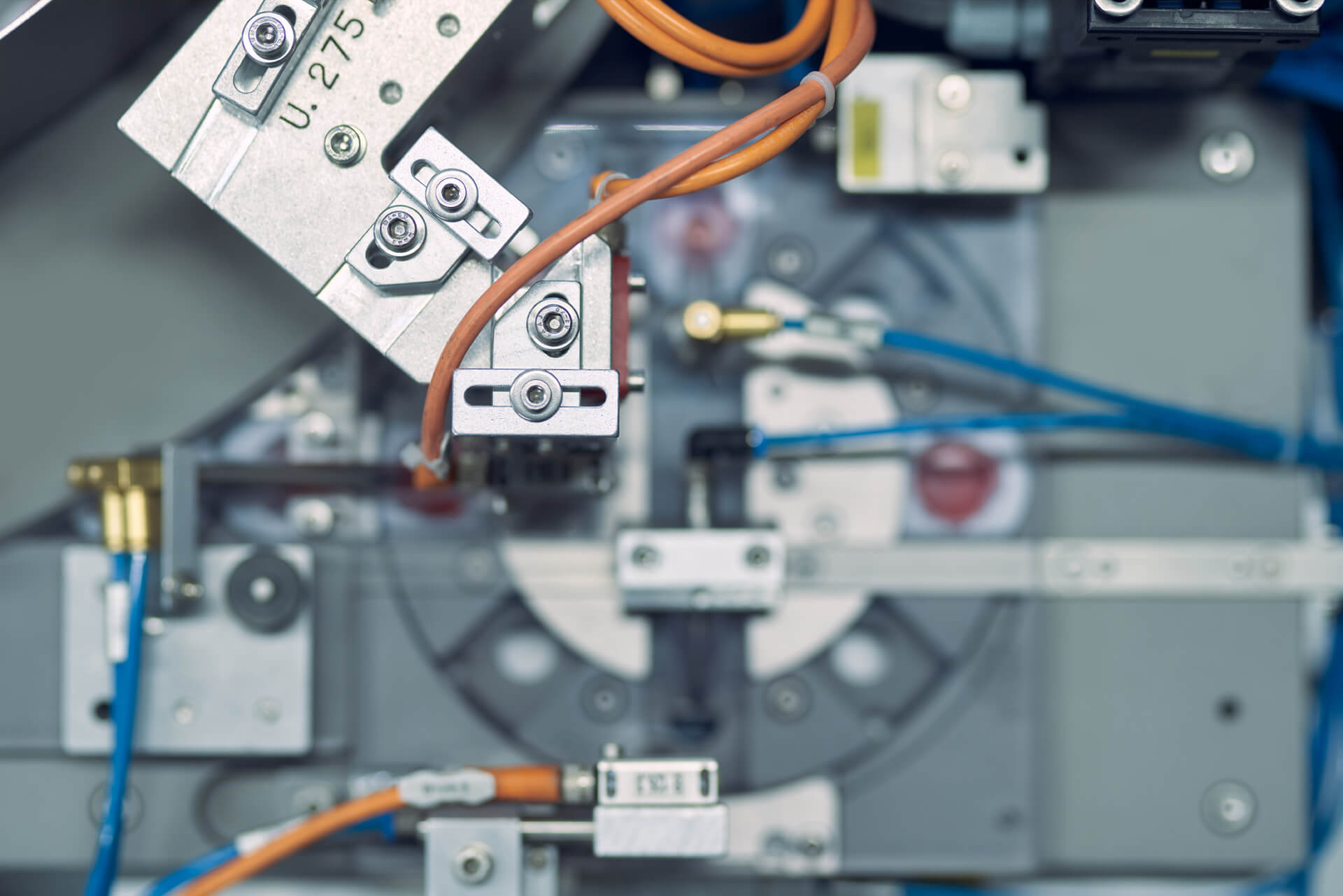

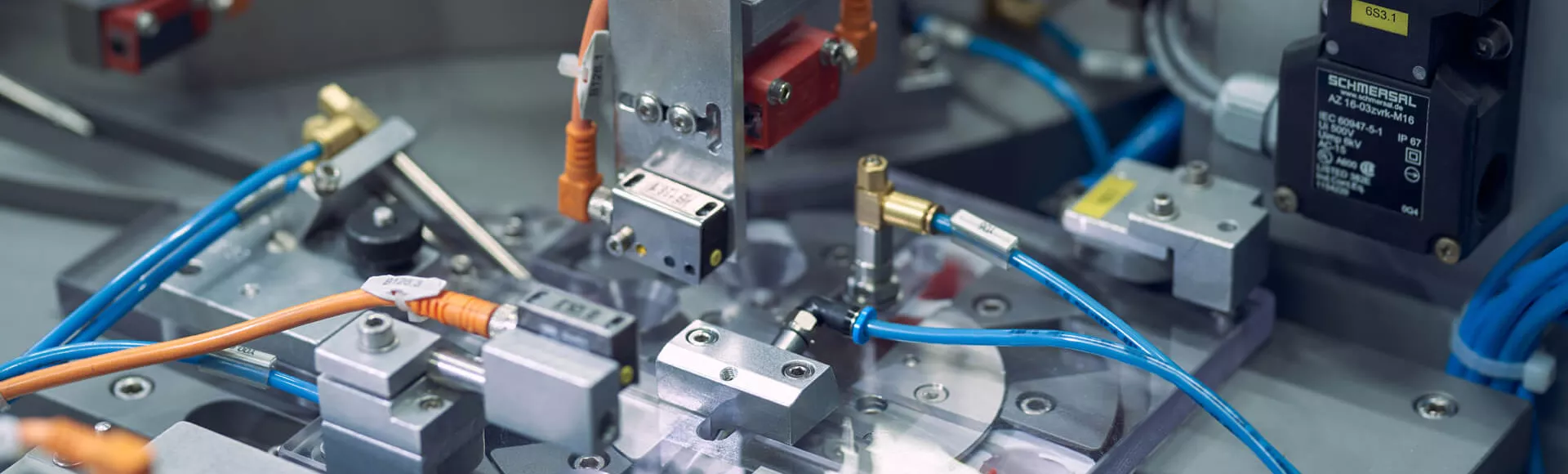

The Centrifugal Feeder BG500 accomplishes several tasks and, due to its modular design, can be retrofitted and adapted to new specifications at any time. Through its combination of various testing devices as well as the many expansion options, it can be tailored perfectly to your needs.

High quantities even with asymmetrical components

While symmetric quantities of 60,000 parts per hour can be processed, the centrifugal feeder ensures output of up to 20,000 parts per hour even with asymmetrical parts leaving the feeder in two directions. Overall, the numbers are significantly higher than vibratory conveyors.

Modular construction and versatile use

The Centrifugal Feeder BG500 has been designed by SMR GmbH to be suitable for work in the food industry. In general, however, the feeder can be used in many different industries—here its modular design is a big advantage, because it means it can be adapted quickly when changing products. Using the available package of exchangeable components, on-site conversion is not only possible, but it can even be carried out by your own employees.

Variety of expansion options

In order to benefit as much as possible from our Centrifugal Feeder BG500, we offer you various expansion options. From noise-reduction casing to the appropriate sensors and pneumatics for detecting and discarding defective parts as well as the integration of testing technology, various options can be implemented. An intelligent control system and the specification of individual interfaces are also part of the comprehensive package.

SMR Sondermaschinen GmbH: innovation with the Centrifugal Feeder BG500

Innovation, efficiency and individuality—this is what the developments of SMR have stood for since 1991. The Centrifugal Feeder BG500 demonstrates this in an impressive manner. With it, optimized results as well as numerous optional and customization possibilties are possible. We would be happy to help you decide whether the Centrifugal Feeder BG500 is the right machine for your production. Especially in combination with other conveyor systems as well as special-purpose machines, we would like to show you how to optimize your production. Contact us today without obligation so we can take your automation processes in a new direction together.